“安徽天孚智能制造”产业链以AI人工智能为核心,立足于服装智能制造产业,是面向未来的下一代服装制造生产模式。与中国提倡的节能环保,人工智能,工业4.0及现代服务等产业相契合。建厂在安徽池州。

首期工厂于2020年4月投产,是国内领先的人工智能服装标准化智能生产中心。全链条依靠机器深度学习驱动,形成以数据中心为核心的服装多品类制造模块化工厂,在执行标准化生产的同时,可以实现无限拓展。另外,服装标准化智造研究院将源源不断的把前沿技术落地到智能制造中心,使得智能制造中心在细分赛道始终保持领先的位置。

"Anhui Tiform Intelligent Manufacturing has an industry chain centered around AI (Artificial Intelligence) and is rooted in the intelligent manufacturing of clothing. It represents a next-generation production model for the future. Aligned with China's emphasis on energy conservation, environmental protection, AI, Industry 4.0, and modern services, the factory is located in Chizhou, Anhui."

"The initial phase of the factory commenced operations in April 2020, establishing itself as a leading domestic AI clothing standardization and intelligent production center. The entire production chain relies on machine deep learning, forming a modular factory for the diversified manufacturing of clothing with a data center at its core. While adhering to standardized production, it allows for unlimited expansion. Additionally, the Clothing Standardization and Intelligent Manufacturing Research Institute continuously integrates cutting-edge technologies into the intelligent manufacturing center, ensuring its leading position in specialized fields."

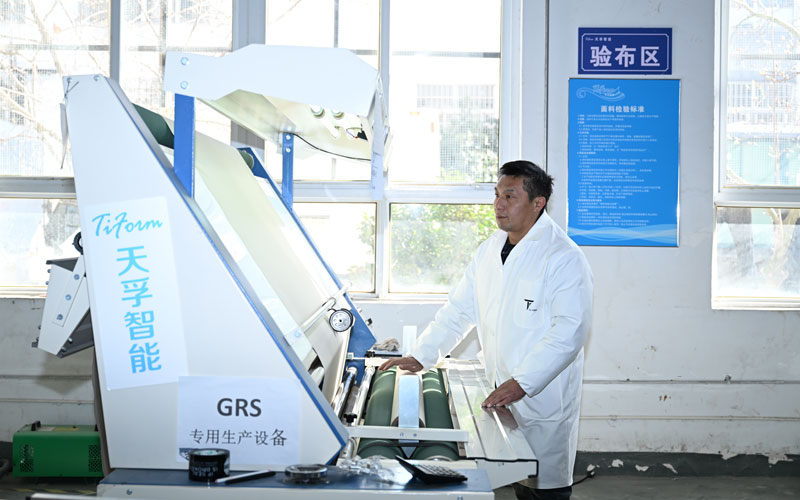

验布区

Fabric Inspection Area

线外区

Off-line Area

技术部

Technical Department

裁剪区

Cutting Area

分片区

Segmentation Area

挂片区

Hanging Display Area

总检区

Final Inspection Area

模版区

Template Area

大烫区

Hot Stamping Area

验针区

Inspection Needle Area

包装区

Packaging Area

成品区

Finished Goods Area

安徽天孚智能制造拥有全自动吊挂系统,自动裁床,吊挂流水线,重机自动合缝机,重机开袋机等一系列先进设备,不仅实现了全自动流水作业从而缩短生产周期,提高生产效率,更实现了产品的可追溯性和品质管控。年产值可达40万件。

"Anhui Tiform Intelligent Manufacturing boasts a range of advanced equipment, including a fully automated hanging system, automatic cutting bed, hanging assembly line, heavy-duty automatic sewing machine, and heavy-duty bag opener. This comprehensive setup not only achieves fully automated assembly to shorten the production cycle and enhance efficiency but also ensures product traceability and quality control. The annual output can reach up to 400,000 pieces."